In the world of engineering and product development, understanding and optimizing the behavior of fluids—whether they are gases or liquids—is often a critical component of success. This is where Computational Fluid Dynamics (CFD) analyses come into play. In this blog post, we’ll explore the compelling reasons why companies might need CFD analyses to enhance their designs, improve efficiency, and mitigate risks.

1. Design Validation and Optimization

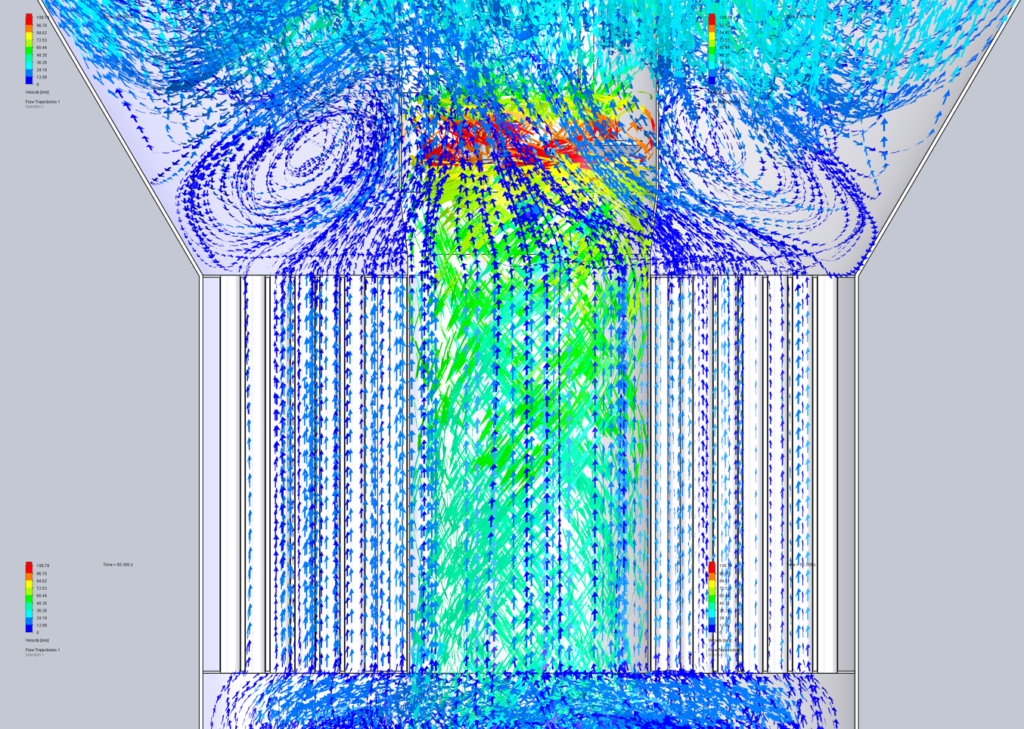

One of the primary reasons companies turn to CFD analyses is to validate and optimize their designs. Whether you’re designing a high-performance race car, an energy-efficient HVAC system, or an innovative aircraft, understanding how fluids interact with your design is paramount. CFD simulations allow you to visualize and analyze fluid flow patterns, heat transfer, and pressure distribution, helping you refine your design for optimal performance.

2. Performance Enhancement

CFD analyses provide valuable insights into how your product or system will perform under different conditions. For example, in the automotive industry, CFD simulations can help optimize aerodynamics to reduce drag and improve fuel efficiency. In the pharmaceutical industry, CFD can be used to enhance drug delivery systems, ensuring medications reach their target with maximum effectiveness.

3. Risk Mitigation

Understanding how fluids behave within a system can help mitigate potential risks and failures. In industries like oil and gas, where pipelines and equipment are subjected to extreme conditions, CFD analyses can predict potential issues such as turbulence, erosion, or corrosion, allowing for preventive measures to be implemented before catastrophic failures occur.

4. Energy Efficiency and Sustainability

In an era where energy efficiency and sustainability are paramount, CFD analyses play a crucial role. By optimizing fluid dynamics within systems like industrial processes or data centers, companies can reduce energy consumption, lower operating costs, and minimize their environmental footprint.

5. Cost Savings

CFD analyses can lead to substantial cost savings by eliminating the need for costly physical prototypes and extensive testing. Simulations allow engineers to explore various design options virtually, identify potential issues early in the design process, and make informed decisions to optimize performance and efficiency.

6. Complex Systems Understanding

In industries with highly complex fluid systems, such as aerospace or nuclear power, CFD analyses provide a comprehensive understanding of fluid behavior. This knowledge is invaluable for ensuring the safety and reliability of systems that operate under extreme conditions.

7. Competitive Advantage

Companies that embrace CFD analyses gain a competitive advantage. They can innovate more rapidly, design products with superior performance, and bring them to market faster. In highly competitive industries, this advantage can be a game-changer.

8. Compliance and Certification

In regulated industries like healthcare or aviation, compliance with safety and quality standards is non-negotiable. CFD analyses can assist in meeting these requirements by providing evidence of design reliability and performance.

9. Real-World Insights

CFD analyses simulate real-world conditions, allowing engineers to uncover insights that might be impossible or too costly to obtain through physical testing alone. This virtual experimentation accelerates the design and development process.

10. Cross-Industry Applicability

The versatility of CFD analyses is striking. They have applications across a wide range of industries, from automotive and aerospace to energy, healthcare, and environmental engineering. This broad applicability makes CFD a valuable tool for companies of all types and sizes.

In conclusion, Computational Fluid Dynamics analyses are indispensable tools for companies aiming to achieve excellence in product design, performance optimization, risk mitigation, and sustainability. Whether you’re striving to create more efficient engines, enhance environmental sustainability, or develop cutting-edge medical devices, CFD analyses offer a window into the behavior of fluids that can drive innovation and competitiveness. Embracing CFD is not just an option—it’s a strategic imperative for modern engineering companies.