Simulation & Analysis

Flow pattern

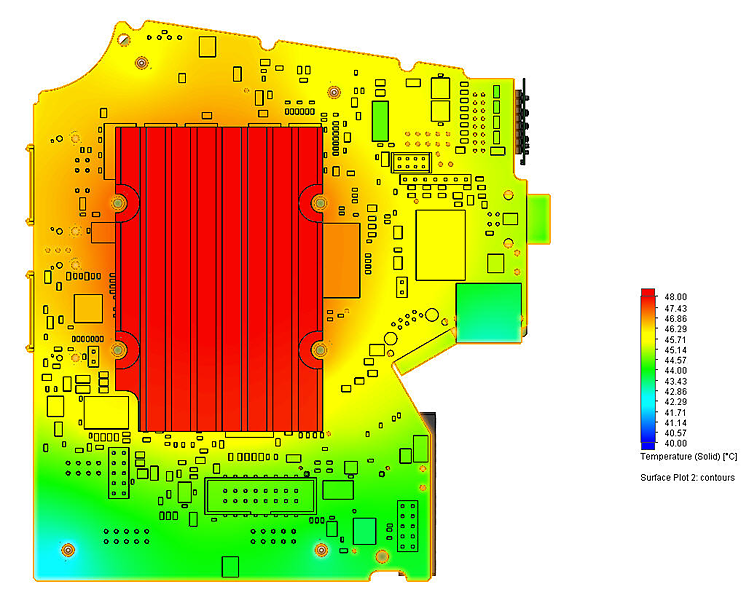

By carefully simulating a product we can accurately predict how hot certain areas and components are going to get. By modifying geometry we can achieve whatever conditions are desired.

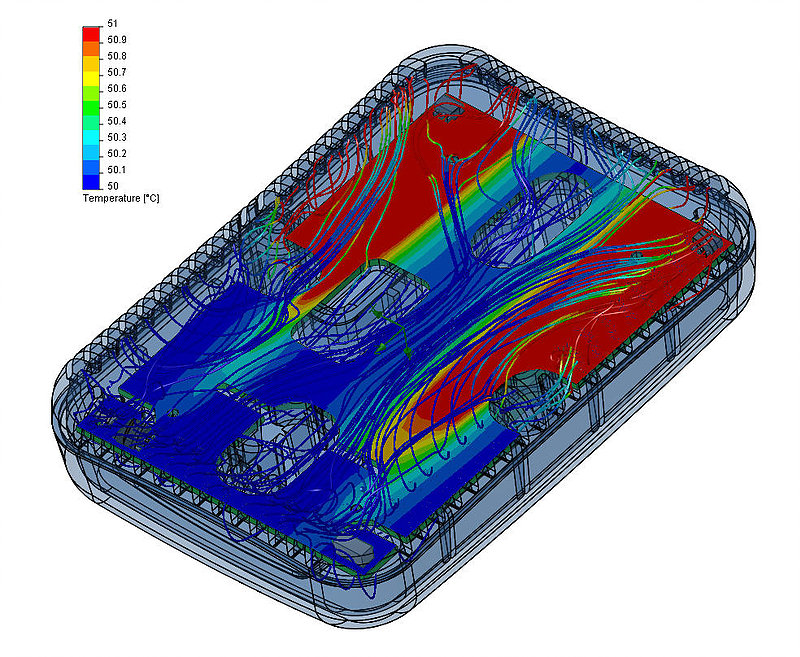

Thermal Design

Sometimes just allowing air to flow freely over heat generating electronics is not enough. In this case we needed to add three fans to provide the cooling.

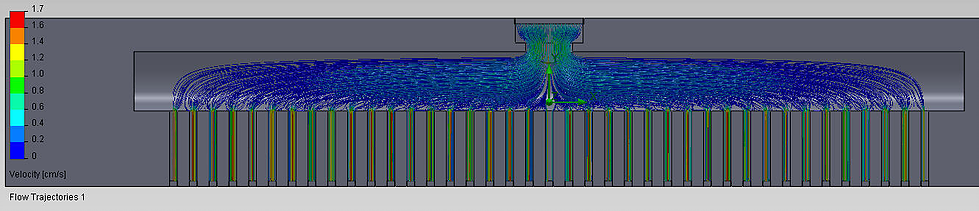

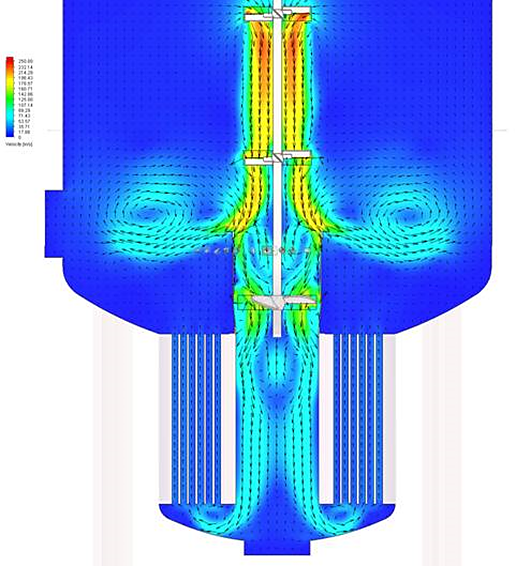

Tablet Glue Machine

The leading manufacturer of tablets found out that their glue machines were limiting their ability to satisfy demand. Their current robotic dispensers and nozzles could not lay down a uniform amount of glue in less than 12 seconds. We redesigned the glue stations and nozzles using CFD simulation software to reduce the application time to less than 3 seconds and simultaneously improve how uniform the application was.

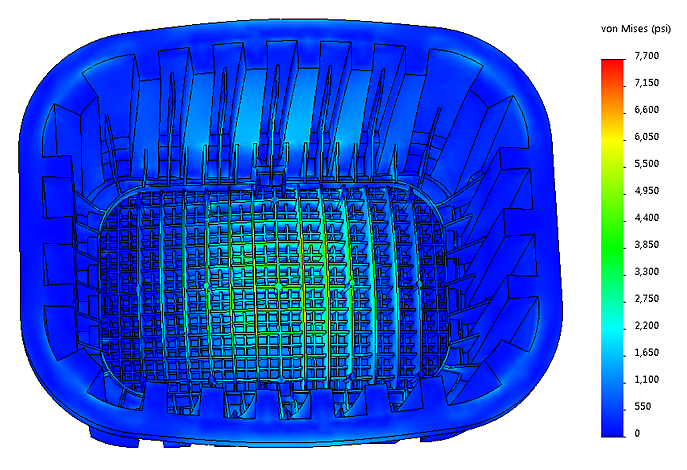

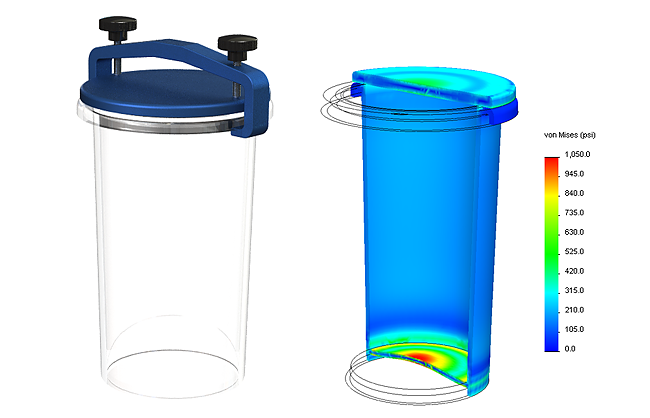

Weight Reduction

This pressurized enclosure was popular with customers but the margins were very low due to the expensive part costs. designPORT simulated the internal pressures and stresses then reduced the volume of material by 40% without sacrificing performance or safety. The result is that this is now one of our clients most profitable items.

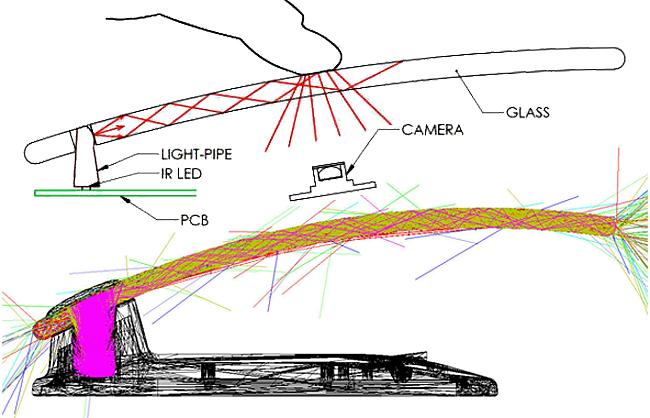

Glass Keyboard

To eliminate all of the nooks and crannies in a conventional keyboard we designed this solid glass surface that can detect where and when a finger touches it. Our ray tracing software was used to design the delicate facets in the glass and properly position the LED’s. *Voted Last Gadget Standing at the CES show in Vegas

Flow pattern

Complete mixing is critical when building an industrial chemical reactor. We developed this simulation to test various configurations before fabrication.

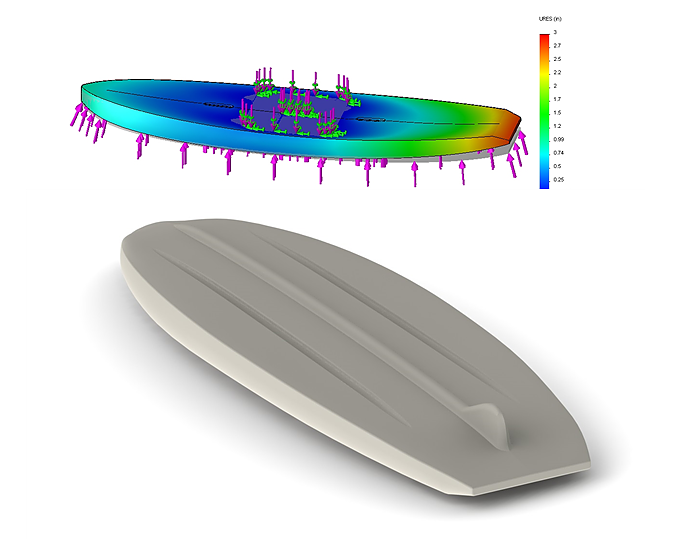

Stand Up Paddleboard

A balance between stiffness and lightweight. Finite element analyses lets us try numerous combinations of variables before getting it just right.

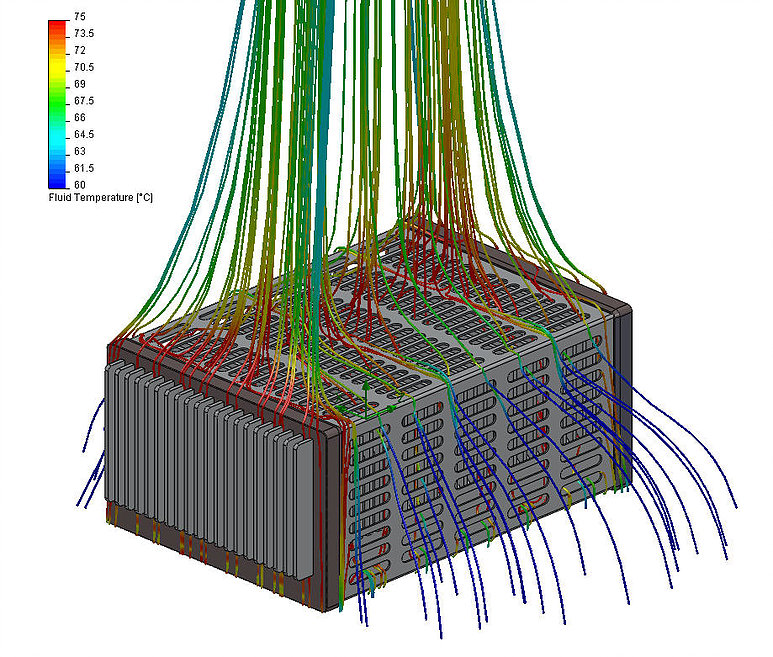

Thermal Solutions

Thermal simulation means better performing heat sinks.

In Ground Junction Boxes

We used Finite Element Modeling to simulate the pressure of a truck driving over these buried vaults. Iterating to achieve the desired factor of safety gave us confidence before building molds.